Crankshaft Restoration and High-Performance Component Services

Extending Engine Life with Precision Engineering

Our Journey

Committed to

Excellence and Innovation

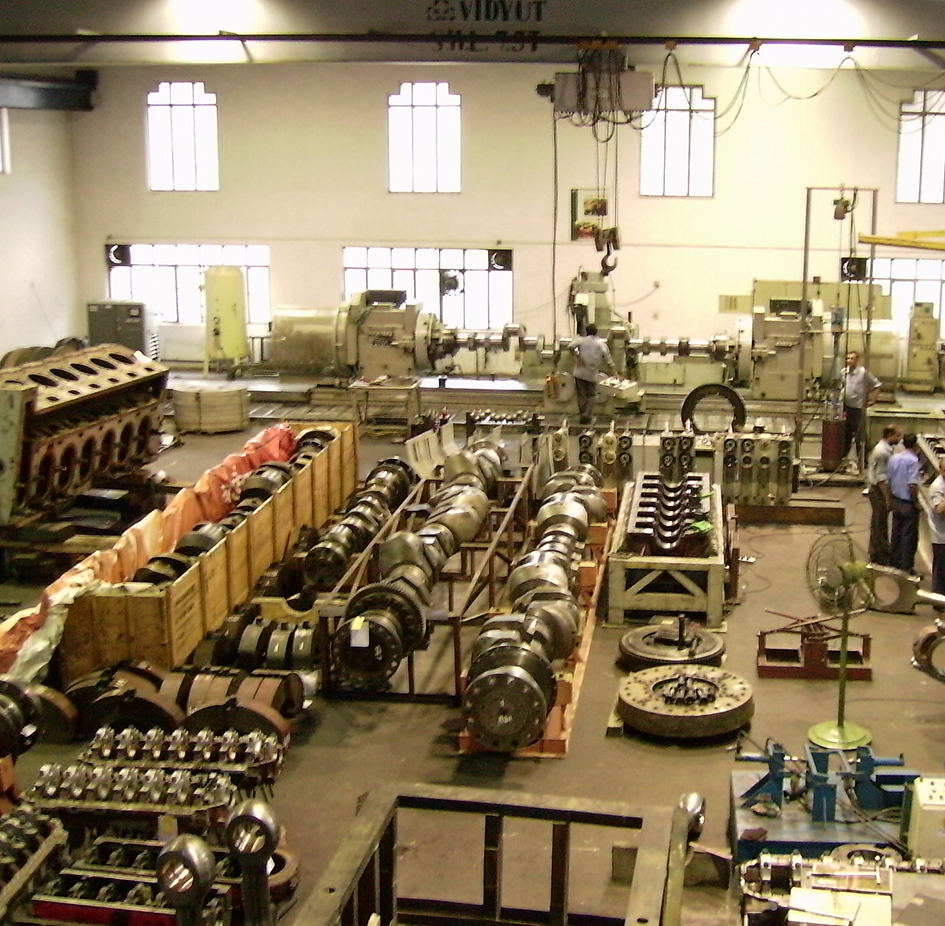

For over 50 years, Tanna Cranktech Pvt. Ltd. has been a trusted name in the Marine, Industrial, and Oil & Gas sectors, delivering excellence in crankshaft repair, reconditioning, and precision engineering services.

Our team’s unmatched technical expertise and commitment to excellence enable us to minimize downtime, reduce costs, and extend the life of vital components for our clients.

At Tanna Cranktech, we specialize in repairing and restoring major engine and machinery components used in:

- Marine engines & ship machinery

- Land-based power plants

- Diesel engines and compressors

- Oil & Gas mechanical systems

Our Specialized Services

What We Can Offer

At Tanna Cranktech we undertake the reconditioning of the heavy-duty , Crankshafts, Cylindrical Shafts, Metal Stitching of several cast iron parts where the welding is not possible / permitted, rebuilding of shafts crankshafts , Line Boring of Engine Blocks, repairing of Cylinder heads, Connecting Rods, boring and Honing of Cylinder Liners, Straightening of Crank Shafts & Cam shafts etc for all Major Diesel engines irrespective of any ,make & capacity worldwide.

○ In-SITU Repairing of the Crankshafts

In cases where the damage in the crankshaft is only in one or few CR pins & all the main journals are ok, economics do not justify the dispatch of the entire CRANKSHAFT to a distant workshop. With the latest edition of the In-situ grinding Machine, a far more flexible solution is offered by TCPL to the customer to repair the damage seized CR pins at the vessels only . We maintain the accuracy in the range of 0.015 to 0.02 mm after the insitu grinding & also the parallelism / taper / ovality are also maintained in the same accuracy range / as per global STD prescribed by OEM .

○ Metal Stitching of the Engine Blocks

Metal stitching is a commercial method of repairing the crack, broken, or burst pieces of cast iron items without application of any heat & as a result of which there is no change/distortion/deformation in the repaired equipment. In the repairing process Locks & Cast master, stitching pins are used. We Import the materials from the USA. The advantages of Metal Stitching are no heat stresses are induced, no distortion occurs. The repair is Gas & Liquid proof & can withstand high pressure & tensional forces & not much machining is required after repairing.

○ Line boring of engine blocks for main journal pockets, liner seating areas, or any equipment with multiple bores in a single line.

The Line Boring of Engine Blocks, Bed Plates, compressor blocks, and gearbox blocks are undertaken by us at site . We are capable of machine two or more bores in a line up to the length of 10 meters with an accuracy level of 0.02mm. We have imported the hydraulic/pneumatic Line Boring equipment which is used for line boring operation. To check the alignment of Bores, an Easy-Laser alignment checking equipment is imported from Sweden, is used. With this laser equipment, alignment of housing bores along “X” & “Y” axis with an accuracy of 0.01mm can be checked.

○ Boring and Honing of Cylinder Liners

The Cylinder Liner boring and Honing is carried out with the machine which is imported by us from a world’s leading company -M/S Chris Marine, Sweden who masters the art of manufacturing of high quality Cylinder Liner boring/honing equipment. The limit of accuracy of re-honed Liners taper/ovality are maintained within 0.02-0.03 mm and the surface finish is controlled within RA1.3-1.6 um & the cross-honing angle is maintained within 45-55 Deg or as per the OEM guide lines / requirement . The machine is portable, so we can undertake the honing operation at the customer’s location .

○ NDT Testing of Engine Components

○ Connecting - Rod Housing Repair

The company has developed technology to salvage expensive Conrods housings by repairing them in-house for correction of the ovality which develops during operation. Crack testing is done to determine invisible cracks & correction of the dimensional wear. In-housing Boring is done & during this process straightness, Parallelism, and center distance are maintained as per OEM STD during the repairing process so that the accuracy of the repair and finish is achieved as per OEM specifications/tolerances.

○ Rebuilding of Crank Shafts

○ Cylinder Heads Repairing

○ Repairing of Engine Components

○ Our Production Facilities

On-Site Services

Services at Mumbai Plant

Manufacturing Facility at Rajkot

Dubai Division :

NDT Inspection for Engine Components

Certified Experts in Precision Engine Testing

We offer advanced NDT inspection services for engine components, including crankshafts, engine blocks, connecting rods, cylinder heads, liners, and camshafts. Our Level II and III certified NDT engineers ensure precise defect detection, quality assurance, and maximum engine reliability, delivering trusted, high-performance inspection solutions that meet international standards.

Precision NDT Techniques

Employing ultrasonic, magnetic particle, and dye penetrant testing for accurate defect detection.

Certified NDT Experts

Our Level II and III qualified engineers ensure compliance with international inspection standards.

Engine Component Check

Detailed NDT inspection of crankshafts, cylinder heads, liners, camshafts, and engine blocks.

Reliable Quality Control

Delivering precise data-driven evaluations to enhance engine performance, reliability, and safety.

What Our Clients Say

Testimonials

Our clients trust Tanna Cranktech for precision engine components and reliable performance. Expertly crafted crankshafts, camshafts, and NDT‑tested parts ensure maximum efficiency, durability, and satisfaction.